Ancel S1000 would assist maintenance technicians to carry out leak detection tests opportunely after your car enters the car repair shop. The leak detection test is the most basic but definitely significant test during car repair. Troubleshooting pipeline leakage problems can help fix car faults and eliminate engine lights effectively,due to 60% of the engine lights are caused by pipeline leakage. With the superb design, the leak detector can discover leakage holes as small as 0.2mm. Adopts the principle of isolated heat conduction, the smoke created from the machine is non-toxic. To ensure the safety of people and vehicles, the engine does not need to be ignited during use. Unlike the traditional method of using soapy water, only the upper half of the complex pipeline can be tested, cars are tested for all-round pipeline leakage.

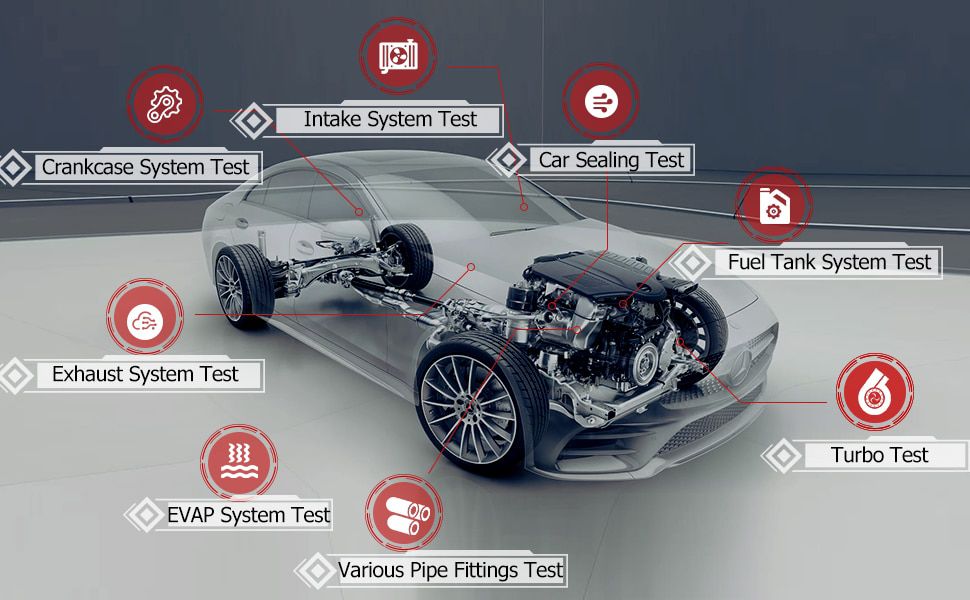

Full System Diagnostics, Don't Miss Any Leaks.

Crankcase System Test:

Excessive pressure or corrosion of the crankcase is the main reason to damage the seal of the crankcase and cause oil leakage.

Intake System Test:

Leakage in the air intake system will lead to insufficient intake of the car engine, which will result in scant engine power.

Car Sealing Test:

Poor airtightness of the car may lead to a lot of inconvenience like inability to keep warm dusty, not soundproof, and not waterproof , etc.

Fuel Tank System Test:

When there are gaps in the fuel tank and piping caused by improper installation or insufficient sealing of the fuel tank cap, it can cause leaks in the fuel tank system.

Turbo Test:

The leakage of coolant would cause the engine to report high water temperature.

Various Pipe Fittings Test:

Smoke testing of brake hoses, power steering hoses, cooling system hoses, air conditioning system hoses, turbocharger hoses, fuel hoses, intake and exhaust system hoses, etc.

EVAP System Test:

Leakage of the fuel evaporation system will cause fuel vapor to leak into the atmosphere, causing waste and pollution or unstable engine idling.

Exhaust System Test:

Unpurified harmful gases to be discharged into the atmosphere or increase vehicle noise is the main disadvantage when leaks happened in the exhaust.

[Reasonable Air Control and Smoke Control Buttons]:

Turn on the air control switch, connect a pressure gauge to the pipe or use a stethoscope to check whether there is a squeak, you can check whether there is a leak. If you want to know the source of the inspection leak, you can find it by turning on the smoke control.

[Clear and Easy-to-Understand Indicator Lights]:

Through the indicator light, you can tell the current state of the machine, or whether the machine is overheated

[Intimate Fuel Volume Line]:

show you the real fuel volume and when you need to refuel or whether the fuel volume is too high.

[Velcro on the side]:

a useful design for collecting power cords and smoke transmission hoses

[Equipped Funnel]:

an auxiliary method to replenish the smoke oil to prevent the oil from splashing on the surface of the unit.

[Intake Bladder Replacement Rubber]:

The rubber on the Intake Bladder may be easily broken, if not operate properly with caution. The rubber could be replaced with a new one without replacing the whole Intake Bladder.

[Adapter Cone]:

help sealing different sizes of air intake and exhaust ports.

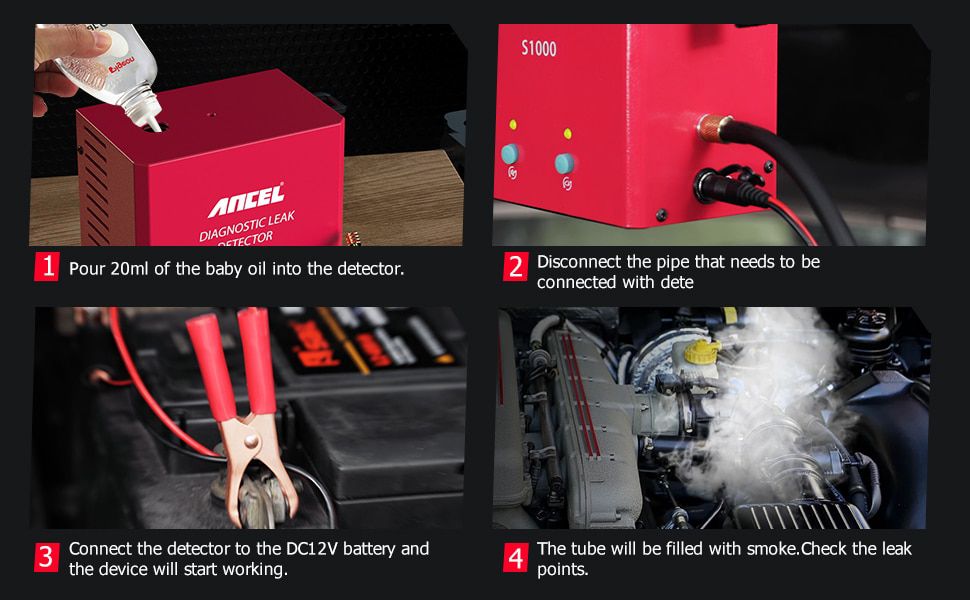

How to carry out leakage detection?

Step 1: Turn off the power to the car, remove the air filter and throttle connector. Note: If you need to test the EVAP system, you need to manually close the solenoid valve

Step 2: Pour baby oil between the max and min oil volume line, connect the power cord to the 12V car battery, choose the appropriate adapter cone to connect the smoke nozzle and the system.

Step 3: Press the air control switch, wait for 30 seconds, and listen for the squeaking sound to check whether there is a leak in the pipeline or not.

Step 4: Press the smoke control switch, when evident smoke is appearing from the smoke nozzle, reinsert the smoke nozzle into the adapter cone, visible smoke can help you pinpoint the location of the leak.

Step 5: Press the smoke and air control switch again to stop producing smoke and air, test is completed.

Step 2: Pour baby oil between the max and min oil volume line, connect the power cord to the 12V car battery, choose the appropriate adapter cone to connect the smoke nozzle and the system.

Step 3: Press the air control switch, wait for 30 seconds, and listen for the squeaking sound to check whether there is a leak in the pipeline or not.

Step 4: Press the smoke control switch, when evident smoke is appearing from the smoke nozzle, reinsert the smoke nozzle into the adapter cone, visible smoke can help you pinpoint the location of the leak.

Step 5: Press the smoke and air control switch again to stop producing smoke and air, test is completed.

Wide Range of Applications

Suitable for all domestic cars, motorcycles, snowmobiles, off-road vehicles, beaches. Cars, light trucks and speedboats, etc. Using together with auto diagnostic tool, you can find the vehicle problem accurately and diagnose fault.

Using tips

1. Cannot test air conditioning ducts

2. Do NOT use the unit on smoke-sensitive parts. Eg. Lamp housing.

3. The equipment is compatible with mineral oil-based baby oil like Johnson&Johnson Pink bottles.

2. Do NOT use the unit on smoke-sensitive parts. Eg. Lamp housing.

3. The equipment is compatible with mineral oil-based baby oil like Johnson&Johnson Pink bottles.

Pure #5 white oil is the best choice if available.

1. Always confirm Fluid level before use, if the fluid level is low enough to the bottom of the fillerport, it will need a refill.

2. For detecting the leakage of pipe systems on cars, motorcycles, snowmobiles, off-road vehicles, ATVs, light trucks, and speedboats. Suitable for all car models.

2. For detecting the leakage of pipe systems on cars, motorcycles, snowmobiles, off-road vehicles, ATVs, light trucks, and speedboats. Suitable for all car models.